CNC milling da juya su ne m, tsada-tasiri kuma daidai, duk da haka yiwuwa ga CNC machined sassa fadada ko da kara lokacin da ƙarin ƙare da aka yi la'akari.Menene zaɓuɓɓuka?Duk da yake wannan yana kama da tambaya mai sauƙi, amsar tana da rikitarwa saboda akwai abubuwa da yawa da za a yi la'akari da su.

Samfuran Ayyuka

Na farko, menene ƙarshen?Shin don inganta kayan ado ne ko aiki?Idan na ƙarshe, waɗanne sassa na aikin ne ake buƙatar ingantawa?Juriya na lalata, taurin saman, juriya na sawa ko garkuwar EMI/RF?Waɗannan su ne wasu daga cikin tambayoyin da za a amsa don haka, idan mai zane ya san abin da aka sa a gaba, bari mu dubi zaɓuɓɓuka daban-daban.

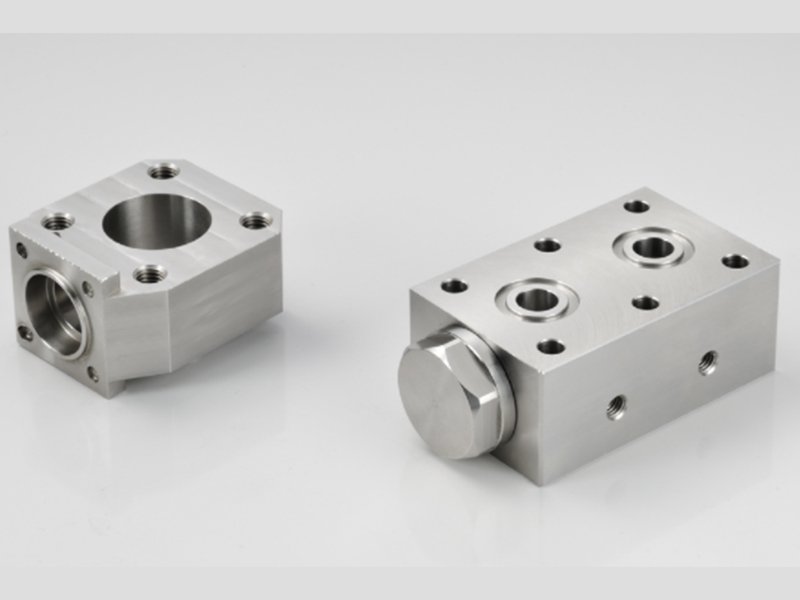

Ƙarfe don Ƙarfe na Ƙarfe na Ƙarfe

A cikin shekaru 40 da suka gabata, an nemi masanan masana'antar Prototype Projects su samar da sassa daga ɗimbin karafa don aikace-aikace a masana'antu da yawa.Ana lalata samfuran akai-akai, ana tsabtace su da kuma lalata su, duk da haka, zaɓin gamawa yana da faɗi sosai.

Yau, mu abokan ciniki 'mafi mashahuri karafa ne aluminum gami 6068, bakin karfe 304 da bakin karfe 316. A gaskiya ma, wadannan uku da ake so akai-akai nema cewa mu rike hannun jari daga gare su a daban-daban masu girma dabam don saduwa da bukatun mu uku-day Express CNC. machining sabis.

Har yanzu shahararru amma ƙayyadaddun ƙayyadaddun su ne jan ƙarfe, tagulla, tagulla na phosphor, ƙarfe mai laushi, ƙarfe na kayan aiki.Daga lokaci zuwa lokaci, abokan ciniki suna buƙatar ƙarfe na musamman.Idan za mu iya samo kayan da injin a cikin gida, za mu yi hakan, in ba haka ba, yawanci muna yin kwangilar aikin ga ƙwararren da aka zaɓa daga cibiyar sadarwarmu ta amintattun shagunan injuna.Misali, manyan allunan kamar Inconel, Monel da Hastelloy suna buƙatar takamaiman dabaru da kayan aiki, don haka yawanci muna fitar da wannan.

Ana iya gama ƙarfe ta hanyoyi daban-daban.Misali, aluminium na iya zama gabaɗaya mai tsabta anodised, rigar gashi anodised, ko baki ko launi anodised.Zaɓin ya dogara da ko abin da ake buƙata shine haɓaka kayan ado ko aikin (musamman juriya mai lalata ko juriya).

Bakin karfe a zahiri yana jure lalata amma wani lokacin abokan ciniki suna ƙayyade ƙarin ƙarewa.Electropolishing, alal misali, yana samar da kyakkyawan ƙarewa da kuma cirewa da cire gefuna daga sassa masu rikitarwa.A gefe guda, idan taurin saman, sa juriya ko aikin gajiya yana buƙatar haɓaka, duka 304 da 316 bakin karfe na iya zama nitrocarburised ko nitrided.

Ƙarfe mai laushi yana amfana daga ƙila mafi faɗin zaɓi na gamawa.Zaɓuɓɓuka sun haɗa da zanen rigar, zanen electrophoretic, shafi foda, electroplating, sinadarai baƙar fata, electropolishing, hardening, titanium nitriding (TiN) shafi, nitrocarburising, da ƙwanƙwasawa, da dai sauransu.

Copper da tagulla yawanci ana keɓance su don sassa masu aiki, ba tare da ƙarin ƙarewa da ake buƙata ba bayan yin injin.Idan ya cancanta, duk da haka, ana iya goge sassa da hannu, goge na lantarki, na'urar lantarki, fashewar tururi, a shafa ko kuma a bi da su da baƙar fata.

Ƙarshen da aka zayyana a sama ba su kaɗai ba ne don ƙarfe da gami.Kullum muna farin cikin tattauna ƙarewa tare da abokan ciniki kuma muna ƙoƙarin taimakawa duk inda za mu iya.

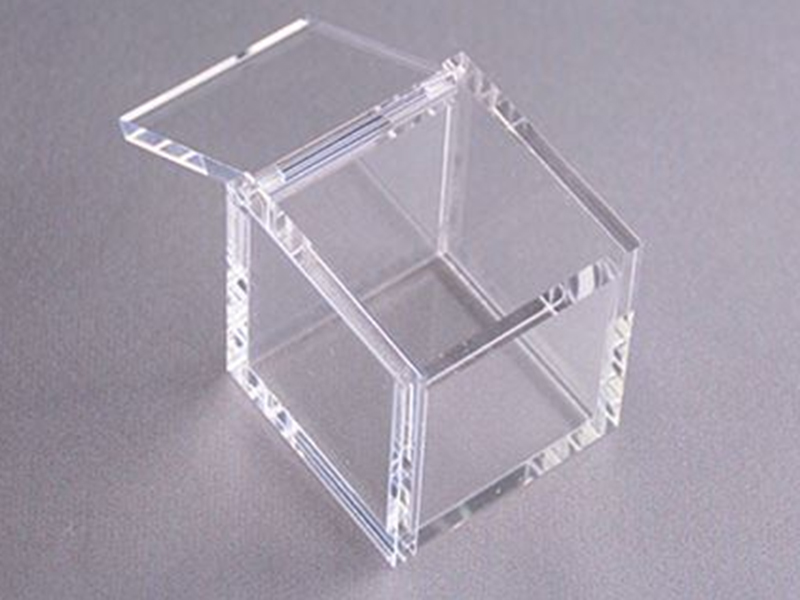

Ƙarshe don Ƙungiyoyin Samfuran Kayan Filastik na CNC

Kamar yadda da karfe sassa, duk na filastik sassa mu CNC inji ana m deburred, tsabtace da kuma ragewa amma, bayan haka, da surface zažužžukan ayan zama daban-daban.

Kamar yadda yawancin abokan ciniki ke buƙatar CNC machined prototype filastik sassa a ko dai acetal (baƙar fata ko na halitta) ko acrylic, muna riƙe nau'ikan nau'ikan filastik.abu a stock.Acetal baya karɓar ƙarin ƙarewa da sauri, don haka ana ba da sassa akai-akai 'kamar yadda aka yi injin'.

Acrylic, kasancewa a bayyane, sau da yawa ana goge shi zuwa bayyanar m.Ana iya yin wannan da hannu tare da sakamako mai kyau na abrasive, ko tare da goge harshen wuta.Dangane da buƙatun mutum, ana iya fentin acrylic tare da fenti na acrylic ko vacuum metallised don cimma wani wuri mai haske sosai.

Wasu daga cikin waɗannan suna da sauƙin gamawa fiye da wasu, don haka koyaushe ana maraba da ku don tattauna kayan da gamawa tare da mu.Game da filastik, za mu iya yashi, firamare da sassa fenti, goge su (da hannu ko ta harshen wuta), farantin lantarki ko vacuum metallise.Ga wasu robobi masu ƙarancin ƙarfi na saman ƙasa, ƙwararrun ƙwararrun ƙwararrun ƙwararru tare da firamare ko magani na plasma ya zama dole.

Matsakaicin Duban Sassan Samfuran CNC Machined

Ɗaya daga cikin dalilan da ya sa abokan ciniki suka zaɓi yin samfuri sassa na CNC maimakon buga 3D shine mafi girman daidaito.Haƙurinmu da aka nakalto don sassan injinan CNC shine ± 0.1mm, kodayake yawanci ana riƙe girma zuwa mafi tsananin juriya, kasancewa ƙarƙashin tsari, abu, da lissafi.Muna bincika girma sosai, ba shakka, abokan ciniki kuma na iya neman takamaiman fasali da aka bincika.

Sau da yawa ana iya ɗaukar ma'aunin tare da masu kira na hannu ko micrometers amma injin mu na haɗin gwiwa (CMM) ya dace don ƙarin cikakken bincike.Wannan yana ɗaukar lokaci kuma baya samuwa tare da ci-gaba na sabis na CNC amma yana da sauri fiye da aika sassan zuwa wani ɓangare na uku don binciken CMM.Keɓance kawai shine lokacin da ake buƙatar cikakken tsari, cikakken shirye-shiryen binciken CMM, ko kuma an yi mashin ɗin sassa kuma ana buƙatar dubawa kashi 100.

Zaɓuɓɓukan Majalisar don Abubuwan Samfurin Samfurin CNC

Ɗaya daga cikin dalili shine abokan ciniki sun zaɓi yin samfur na sassa CNC maimakon buga 3D shine mafi girman daidaito.Haƙurin da aka ba da izini ga sassan injinan CNC shine ± 0.1mm, kodayake yawanci ana riƙe da girma zuwa juzu'i masu ƙarfi, ya danganta da kayan da lissafi.Za mu bincika dukkan sassa kafin jigilar kaya, kuma abokan ciniki kuma za su iya neman takamaiman abubuwan da za a bincika su ma.

Sau da yawa ana iya ɗaukar ma'aunin tare da masu kira na hannu ko micrometers amma injin mu na haɗin gwiwa (CMM) ya dace don ƙarin cikakken bincike.Yana da sauri fiye da aika sassan zuwa wani ɓangare na uku don binciken CMM.Keɓance kawai shine lokacin da ake buƙatar cikakken tsari, cikakken shirye-shiryen binciken CMM, ko kuma an yi mashin ɗin sassa kuma ana buƙatar dubawa kashi 100.

Lokacin aikawa: Juni-30-2022