Menene Maganin Injection?

Yin gyare-gyaren allura kyakkyawan tsari ne mai sauƙi wanda zai iya samar da rikitattun siffofi da sauri don sassa da samfura na al'ada.Yin gyare-gyaren allura shine tsarin zaɓi don kamfanonin da ke neman samar da sassa masu maimaitawa tare da ƙaƙƙarfan buƙatun inji.Yin gyare-gyaren allura kuma sanannen zaɓi ne na masana'antu don gudanar da ayyuka masu girma, ba kawai saboda daidaiton ingancin ɓangarorin filastik da aka kera ba, amma kuma farashin-da-ɓangarorin yana raguwa tare da haɓakar masana'anta masu yawa.

Bugu da ƙari, Huachen Precision yana ba da gyare-gyaren allura wanda ke gudanar da ƙananan sassa 100.Sabis ɗinmu na gyare-gyaren allura yana ba ku damar motsawa cikin sauƙi daga samfuri zuwa samarwa na ƙarshe.

Matakai Shida don Yin gyare-gyare

Allura

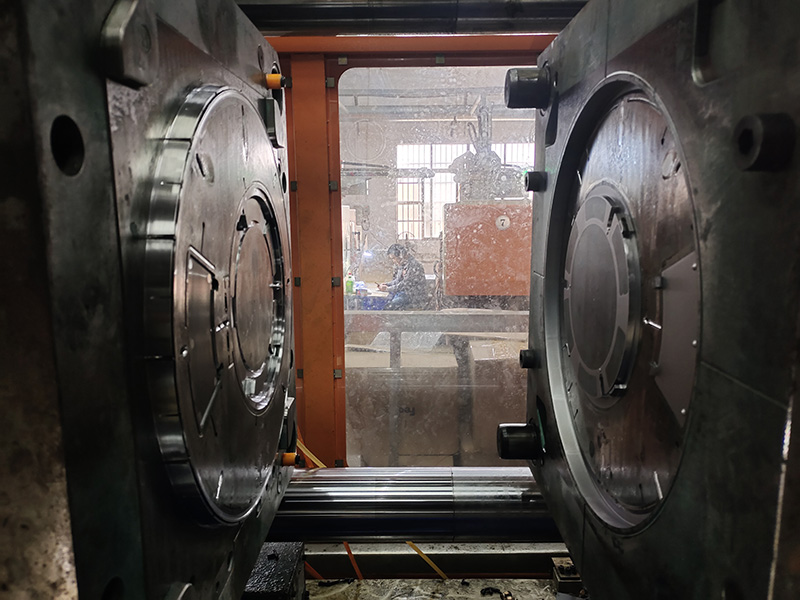

Lokacin da faranti biyu na mold suka haɗa tare, ana iya fara allura.Filastik, wanda yawanci a cikin nau'in granules ko pellets, ya narke cikin cikakken ruwa.Sa'an nan, wannan ruwa ne allura a cikin mold.

Matsawa

Ana yin gyare-gyaren allura a cikin nau'i biyu, nau'i-nau'i irin na clamshell.A cikin lokacin matsewa, faranti biyu na ƙarfe na ƙirar ana tura su sama da juna a cikin latsa mashin.

Sanyi

A cikin matakin sanyaya, ya kamata a bar ƙera shi kaɗai don haka filastik mai zafi a ciki zai iya yin sanyi da ƙarfi cikin samfur mai amfani wanda za'a iya cire shi cikin aminci.

Mazauni

A cikin lokacin zama, robobin da aka narke ya cika gabaɗayan ƙirar.Ana amfani da matsi kai tsaye zuwa ƙirar don tabbatar da ruwa ya cika kowane rami kuma samfurin ya fito daidai da ƙirar.

Fitarwa

Tare da buɗaɗɗen ƙira, sandar fitarwa za ta tura ingantaccen samfurin a hankali daga cikin buɗaɗɗen ƙura.Mai ƙirƙira ya kamata ya yi amfani da masu yankewa don kawar da duk wani abu mai ɓatacce kuma ya kammala samfurin ƙarshe don amfanin abokin ciniki.

Buɗe Mold

A cikin wannan mataki, injin daskarewa zai buɗe sassa biyu na ƙirar a hankali don yin aminci da sauƙi cire samfurin ƙarshe.

Injection Molding Capabilities Manufacturing Capabilities

| Cibiyarmu na magunguna na masana'antu tana ba ku damar samun damar rarrabuwar kawuna don yin masana'antun masana'antun ku. | |

| Suna | Bayani |

| Kayan aikin gaggawa | Molds tare da kayan ƙarfe mai arha tare da lokacin rayuwa har zuwa gudu 20,000.Ana yin injin a cikin yawanci makonni 2-3. |

| Kayan Aikin Kaya | Ƙaƙƙarfan ƙira na gargajiya, waɗanda aka yi amfani da su a cikin yawanci makonni 4-5. |

| Samfuran Kogo Guda ɗaya | Samfuran da ke ɗauke da rami ɗaya kawai, suna samar da raka'a ɗaya a kowace gudu. |

| Molds tare da Side-Action Cores | Motoci suna zamewa daga ɓangaren daga gefe kafin a fitar da shi daga ƙirar.Wannan yana ba da damar ƙera kayan da aka ƙera. |

| Multi-Cavity Molds | Ana sarrafa kogo iri ɗaya a cikin kayan aikin ƙira.Wannan yana ba da damar samar da ƙarin sassa a kowane harbi, rage farashin naúrar. |

| Tsarin Iyali | An tsara sassa da yawa cikin kayan aikin ƙira iri ɗaya.Wannan yana ba da damar rage yawan farashin kayan aiki. |

| Saka Molding | Ana sanya abubuwan da aka saka a cikin ƙirar kuma ana yin gyare-gyare a kusa da su.Wannan yana ba da damar abubuwan da aka saka irin su helicoils da za a ƙera su cikin ƙirar ku. |

| Overmolding | Ana sanya sassan da aka riga aka yi a cikin injin don yin gyare-gyare a kansu.Wannan yana ba da damar yin gyare-gyaren allura da yawa. |

Amfanin Gyaran allura

1.Excellent gudun samarwa don samar da taro

2.Low cost da part da high daidaito

3.Excellent surface ƙare

4.Mafi ƙarfin injina

5.A iri-iri na kayan zažužžukan

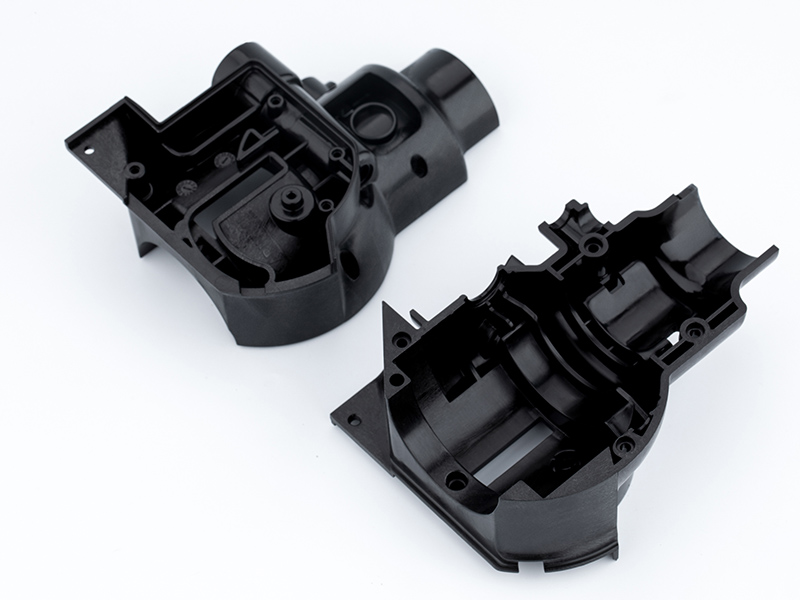

Nunin ɓangarorin gyare-gyaren Filastik na allura

Sashin Gyaran Allura na Musamman

Fitarwa Mod ɗin allura

gyare-gyaren Filastik sassa

Injection Molding White Parts

Ƙananan Kayan aiki