Menene Metal Die Casting?

Die Casting yana nufin tsarin samar da sassa na ƙarfe da aka yi ta hanyar mold.Wannan tsari yana ba da damar samfurori da za a yi a kan sikelin samar da taro tare da babban inganci da maimaitawa.Tsarin yana farawa ta hanyar tilasta narkakkar karfe karkashin babban matsi cikin simintin gyaran kafa ya mutu.Mutuwar na iya ƙunsar kogo ɗaya ko da yawa (cavities sune gyare-gyaren da ke haifar da siffar ɓangaren).Da zarar karfen ya ƙarfafa (da sauri kamar daƙiƙa 20) sai mutuwar ta buɗe kuma an cire harbin (ƙofofin, masu gudu da sassan duk an haɗa su) kuma aikin ya sake farawa.Bayan aikin jefar da mutuwa, yawanci ana ƙara sarrafa harbin akan mutuƙar datsa inda ake cire ƙofofin, masu gudu da walƙiya.Sa'an nan kuma za a iya ƙara sarrafa ɓangaren ta hanyar ɓarnawar girgiza, fashewar fashewar fashewar, injina, zane-zane, da sauransu.

Fa'idodin Die Casting

Aluminum mutu simintin gyare-gyare shine mafi yawan tsari don samar da sassan simintin aluminum da ake amfani da su a masana'antu daban-daban.Kamar yadda aluminium yana da kyakkyawan aiki na kayan aiki, juriya mai lalacewa sosai da kwanciyar hankali mai girma tare da sassan sassa masu siffa.

Aluminum mutu simintin gyare-gyare babban ƙarfin inji ne, mai sauƙin jefawa, kuma yana da ƙarancin farashi idan aka kwatanta da sassan simintin simintin ƙarfe ko magnesium.

Aluminum mutu simintin sassa suna da manyan kaddarorin jiki waɗanda ke jure yanayin zafin jiki, wanda ke sa ana iya amfani da simintin aluminum a cikin motoci, jirgin sama, likitanci, da sauran samfuran masana'antu.

Matakai Biyar

Mataki na 1. Narkewar Abu

Tunda aluminium yana da madaidaicin wurin narkewa (660.37°C) wanda ba za a iya narkewa a cikin injin simintin mutuwa kai tsaye ba.Wannan shine dalilin da ya sa muke buƙatar pre-narke shi tare da tanderun da aka haɗainjin simintin gyaran kafa.

Mataki 2. Ƙauran Kayan Aikin Motsawa da Tsawa

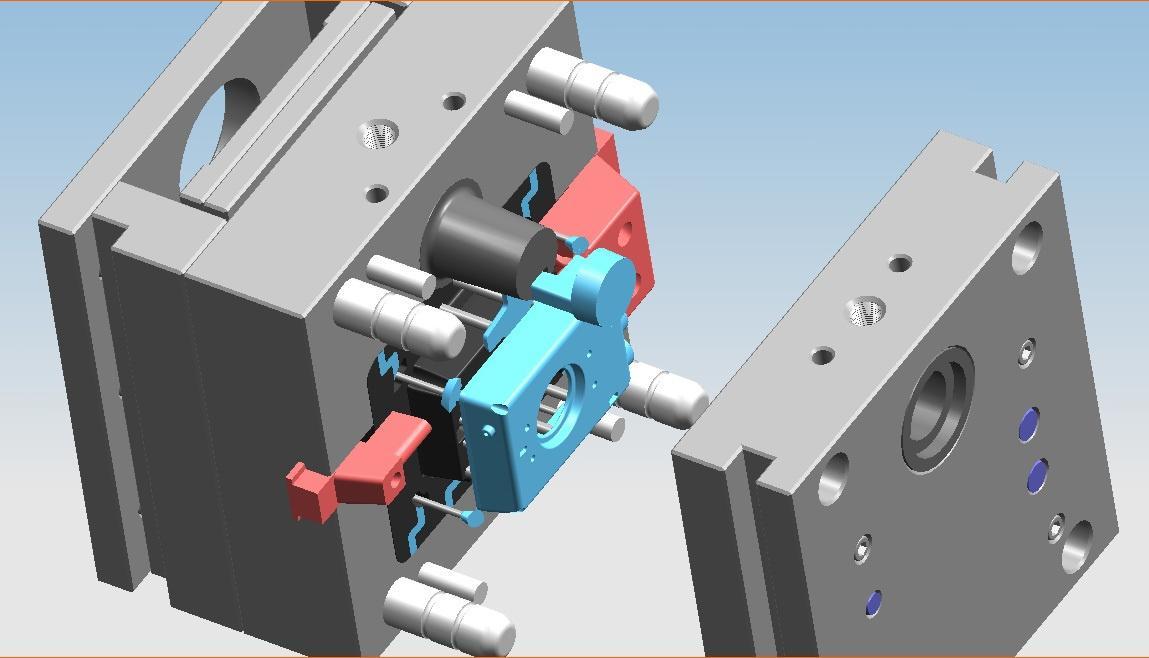

Yana da kusan kama da gyare-gyaren allura, tsarin simintin mutuwa kuma yana buƙatar kayan aikin ƙira don aikin simintin.Sabili da haka, muna buƙatar hawa kayan aikin simintin gyare-gyaren da aka mutu akan simintin sanyi mutuinji.

Mataki na 3. Allura ko Cikewa

Ana canja wurin narkakkar kayan daga tanderun zuwa injin simintin simintin gyare-gyare ta hanyar ladle mai motsi.A wannan mataki, kayan za a zuba da kuma tilasta a cikin mutuwar simintin gyaran kafa mold rami indakayan yana sanyaya kuma yana ƙarfafawa don samun samfuran simintin da ake so su mutu.

Mataki 4. Cool da Solidification

Bayan kayan aikin simintin simintin ya cika da kayan narkakkar, yana ɗaukar daƙiƙa 10 ~ 50 don kwantar da ƙarfi (ya dogara da tsarin sashi da girman).

Mataki na 5. Sashe na Ƙaddamarwa

Lokacin da mold ya buɗe, za a fitar da sassan da aka zubar ta hanyar fitar da fil daga kayan aikin simintin simintin.Sa'an nan kuma danyen simintin gyaran kafa suna shirye.

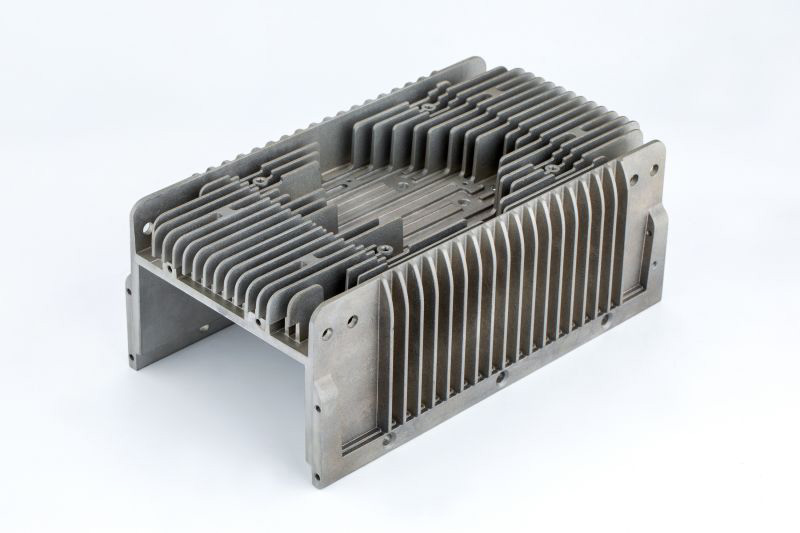

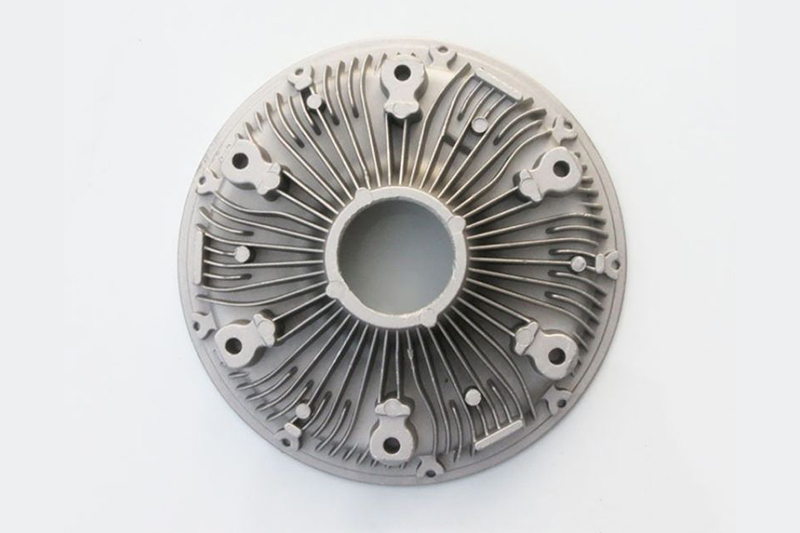

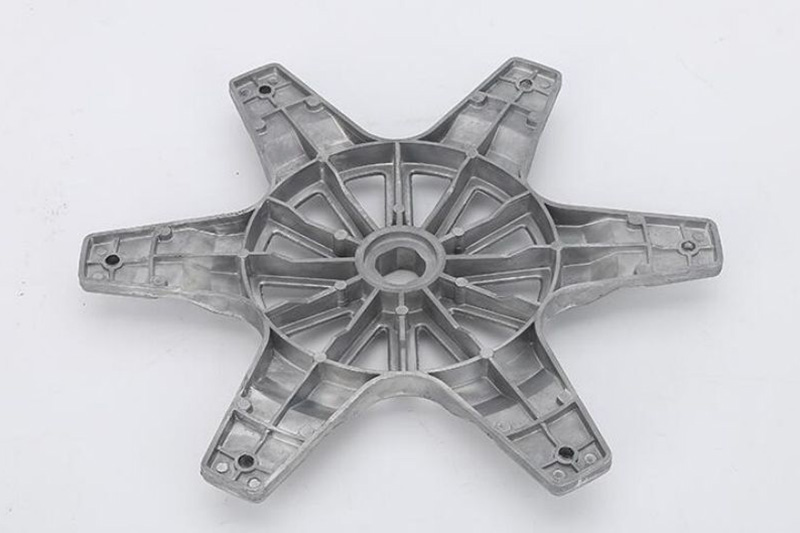

Nunin Nunin Rubutun Casting Parts

Sashin Kayan Aikin Samfuran Sauri

Ƙungiyoyin Ƙarfafa Ƙwararrun Ƙwararrun Ƙwararru

Sashe na Simintin Ƙwararren Ƙwararru

Mutu Simintin Ɗauki Ba tare da Kammala Jiyya ba

Sashin Kayan Aikin Samfura