Menene Fabrication Metal?

Sheet Metal Fabrication hanya ce ta masana'anta wacce ta ƙunshi yanke da lanƙwasa zanen ƙarfe don samar da siffofi daban-daban.Yana da mafi tsada-tasiri fiye da CNC machining idan ya zo ga karfe sassa tare da uniform kauri bango.

Tsarin Ƙarfe na Sheet Metal

Dangane da nau'in ɓangaren da za'a kera, ƙayyadaddun ƙira da ƙarewar da ake so, ana iya samar da zanen ƙarfe a cikin matakai 3 masu sauƙi waɗanda suke yanke, kafawa, da haɗuwa (majalisu).

1.Yanke

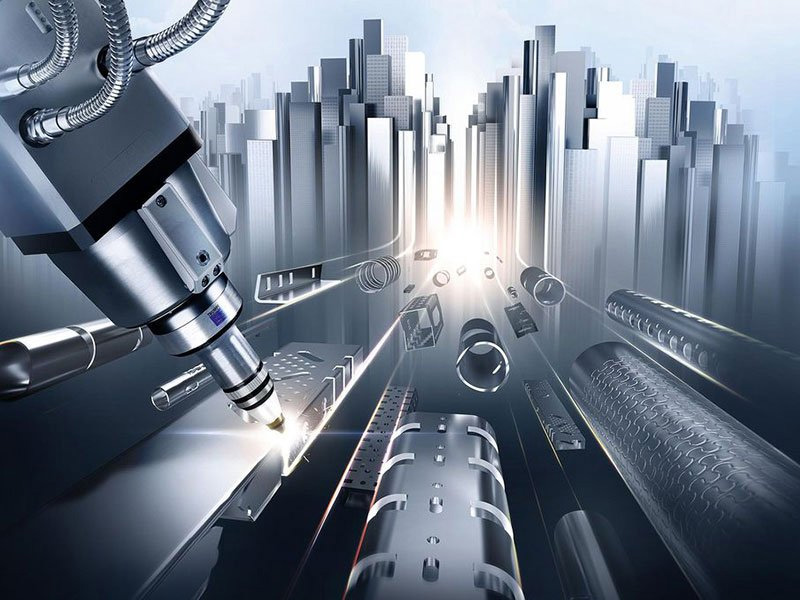

1) Laser yankan:

Yana amfani da hasken haske mai mai da hankali kan Laser don yanke ta cikin zanen ƙarfe.Hakanan za'a iya amfani dashi don sassaka karafa.

Izinin Sheet kauri: 1-10mm (dangane da kayan)

2) Yanke jirgin ruwa:

Babban tsari mai sauri wanda ke jagorantar rafukan ruwa masu tashe-tashen hankula a takardar don yanke cikin kayan.

3) Plasma:

Yankewar Plasma yana amfani da iskar ionized mai zafi wanda ke tafiya cikin sauri kuma yana sarrafa wutar lantarki don yanke kai tsaye a takardar ƙarfe.

2. Samuwar

Ƙirƙira ita ce laima ta gaba ɗaya don matakai kamar tambari, shimfiɗawa, naɗa, da lankwasawa.Ba kamar yanke inda aka cire kayan daga karfen takarda ba, ƙirƙira yana amfani da kayan aikin ƙirƙira kawai don sake fasalin ɓangaren zuwa lissafin da ake so.

3. Lankwasawa

Ana iya yin wannan aikin masana'anta da hannu ko latsa birki, ko amfani da mutu don samar da siffar U-siffa, siffar V ko tashoshi tare da madaidaiciyar axis a cikin kayan ductile.

Kauri mai izini: 1-6mm (dangane da abu)

4.Majalisi

Haɗawa ya ƙunshi matakai kamar riveting, adhesives, brazing, kuma mafi shahara, walda.

5.Welding

Yana iya zama Stick, MIG, ko TIG.Tsarin da gaske yana haɗa zanen ƙarfe biyu ko sama da haka ta hanyar amfani da harshen wuta don narke su tare a gaban mai filler.

6. Tafiya

Haɗa karafa tare ta hanyar haɗa ƙananan sassa na ƙarfe ta cikin zanen gado biyu.

Fa'idodin Ƙarfe na Sheet Metal

Matsakaicin Ƙarfi/Nauyi Ratio

Sassan ƙarfe na takarda suna da ingantacciyar ƙarfin ƙarfi-zuwa-nauyi, yana mai da su ƙarfi mai ɗorewa kuma musamman dacewa azaman samfuran aminci mai ƙarfi da sassan amfani na ƙarshe.

Ƙimar ƙarfi

Ƙirƙirar ƙirƙira ƙarfe na buƙatu da ƙananan farashin saiti don yin sassa a ƙasan raka'a ɗaya zuwa sama da raka'a 10,000.

Saurin Juya Sauri

Tare da iyawarmu da saka hannun jari a cikin kayan aikin ƙira na zamani, za mu iya haɗa matakai na al'ada da fasaha na dijital don sadar da sassan ƙarfe mai inganci.

Bambancin Material da Zabuka

Zaɓi daga kewayon ƙarfe na takarda da yin amfani da abubuwan da suka dace kamar ƙarfi, nauyi, da juriya na lalata don mafi kyawun aiki da ƙarewa.

Tasirin Kuɗi

Yi amfani da sabis na ƙirƙira ƙarfe don ƙirƙirar sassan ƙarshen ku da yawa kuma ku saukar da farashi-kowa-raka.

Ƙararren Ƙarshe

Zaɓi daga tsararrun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aikin ku.Zaɓi daga anodizing zuwa plating, zanen foda-shafi, ko je don ƙayyadaddun bayanai na al'ada.

Zaɓuɓɓukan Abu

· Aluminum

Aluminum yana da kyakkyawan rabo mai ƙarfi / nauyi.Hakanan yana iya jure ƙananan yanayin zafi, yana mai da shi dacewa don amfani a sararin samaniya da fasahar sanyaya.

· Tagulla

Copper yana da babban ƙarfin lantarki.Yana da ductile, malleable, kuma ya dace da abubuwan da ke jure lalata.

· Karfe

Kyakkyawan don aikace-aikacen da ke ba da ƙarfi da ƙarfi.

· Magnesium

Magnesium sheet karafa suna da ƙananan yawa.Su ne don aikace-aikace inda ake so taurin.

· Tagulla

Brass ba shi da nauyi kuma yana jure lalata.Ya dace sosai don yin kayan aiki da kayan aiki da kuma sassan da ke buƙatar kaddarorin sauti.

· Tagulla

Bronze yana alfahari da ƙarfi mafi girma fiye da jan ƙarfe.Yana da ƙarancin narkewa, yana sa ya dace don amfani da injin turbines da kayan dafa abinci.

PS: Abubuwan da ke sama sune mafi yawan zaɓuɓɓukan kayan haja.Idan ba a jera kayan da ake buƙata a sama ba, za mu iya samo muku asali.

Masana'antu

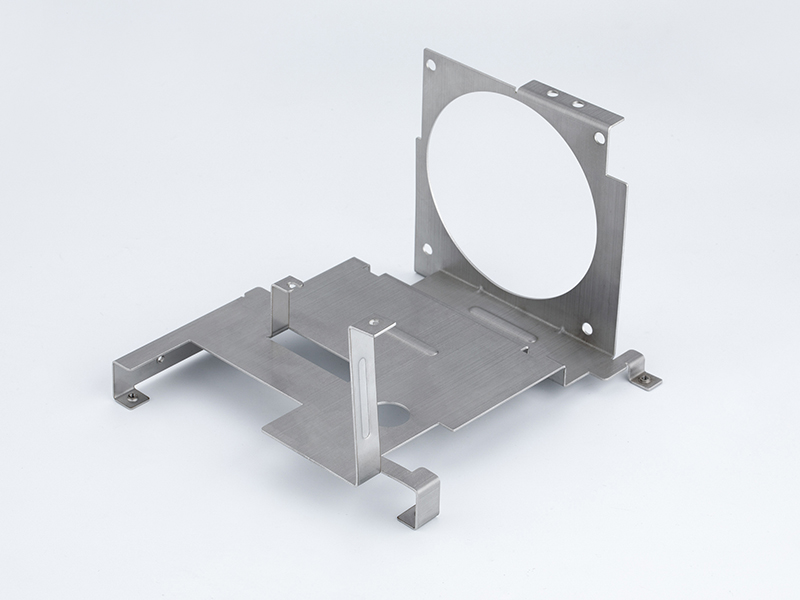

Ƙaƙƙarfan sassa na ƙarfe ana yin su cikin sauƙi su zama shinge na aiki, madaidaici, da chassis ta hanyar sarrafa ƙarfen takarda.Ƙirƙirar ƙarfe na takarda hanya ce mai yuwuwar yin fakitin na'ura, chassis, braket, kwalaye, da marufi na kowane salo don dacewa da na'urorin lantarki da na'ura.

An fi amfani dashi a cikin masana'antu kamar haka:

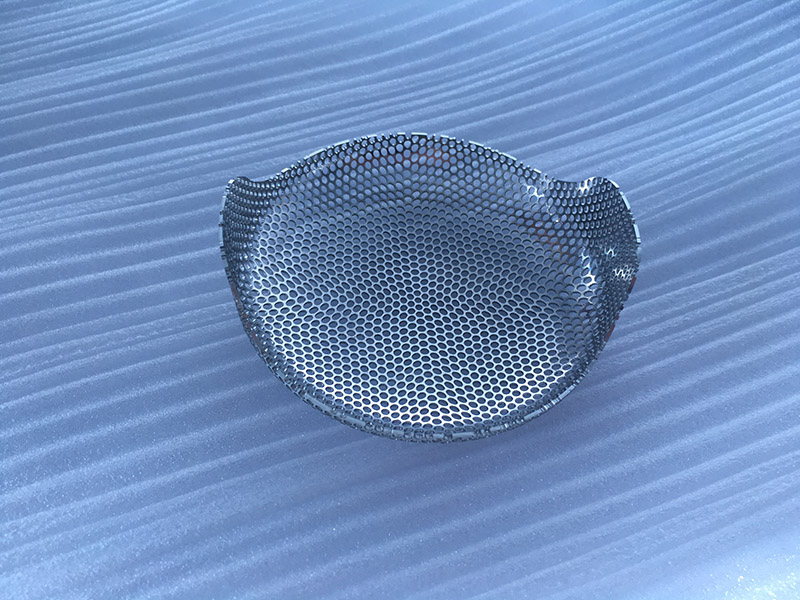

Nunin Ƙarfe na Sheet

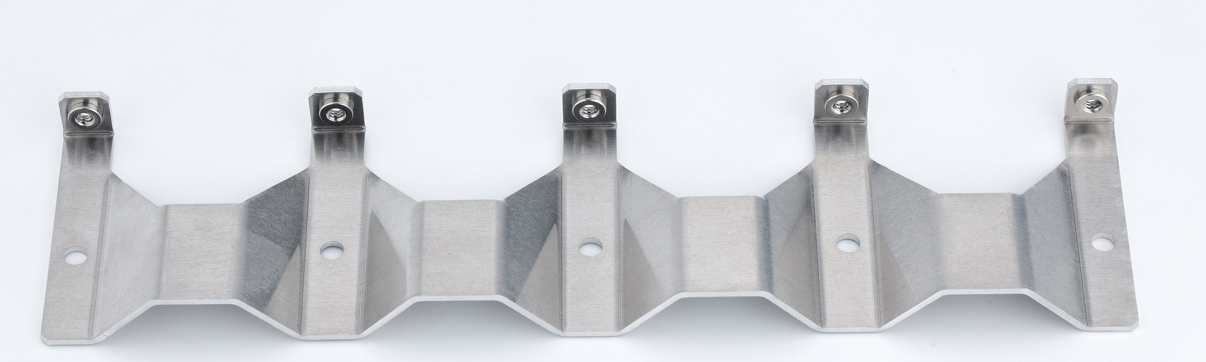

Sashe na Stamping

Bangaren Karfe Bakin Karfe

Sashen Samfurin Saurin

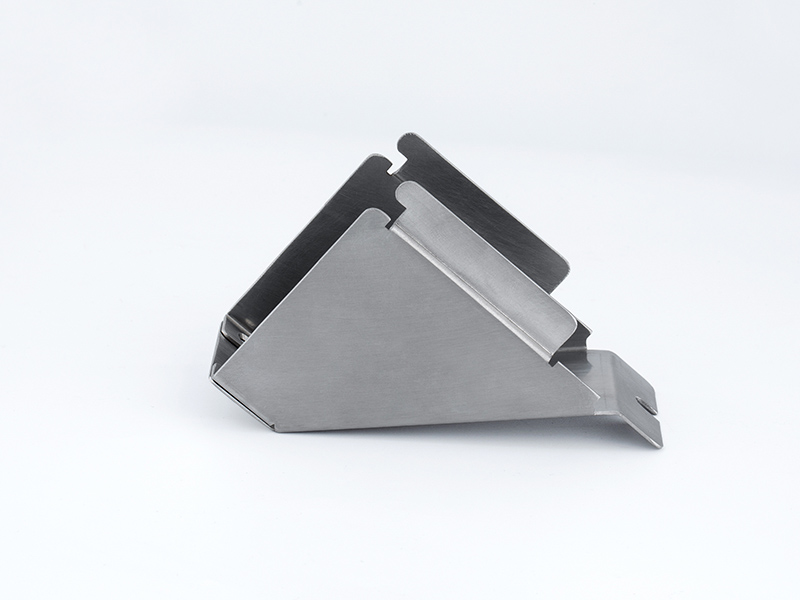

Bangaren Lankwasawa

Sashin Rufe Foda